System Design

All hydraulic ratings and pressures are at the crane, compressor or outriggers. Pressure drops within the hydraulic system is not taken into account. These pressure drops are added to the rating of the hydraulic pump and components. Auto Crane highly recommends consulting a hydraulic expert for specifying the correct hydraulic pump type and size, oil reservoir size, hydraulic cooler, hydraulic pressure relief, and other hydraulic supply components for your application.

Please take into consideration the following: The hydraulic flow and pressure requirements of the crane and air compressor, the continuous hydraulic load when the crane and compressor are running, the duty cycle and ambient operating temperatures, and any other hydraulic equipment that may share the same hydraulic supply system.

Cooling

Trucks which are operated with the PTO continuously engaged will build-up more heat than a passive oil tank can dissipate and will require an auxiliary cooler or additional cooling from another component such as the Vanair RS85 compressor. Auto Crane offers a custom Vanair RS85 with a larger cooler which allows 100% duty cycle.

Hose Sizes

Use a flow capacity nomographic chart such as the one provided by Parker to determine the minimum size hose for pressure, return and suction lines. Click on the image below to see full size chart. Pump suction lines should be in the 2-4 ft/sec range. Return lines should be in the 5-10 ft/sec range. Finally, pressure lines should be in the 10-20 ft/sec range.

The velocity of the fluid should not exceed the range shown in the right hand column. When oil velocities are higher than recommended in the chart, turbulent flow occurs, resulting in loss of pressure and excessive heating.

- For long hoses and/or high viscosity oil, or if the flow of hydraulic fluid is continuous, it is recommended to use figures at the lower end of the Maximum Recommended Velocity range.

- For short hoses and/or low viscosity oil, or if the flow of hydraulic fluid is intermittent or for only short periods of time, figures at the higher end of the Maximum Recommended Velocity range can be used.

The Parker example coincides with a crane-only setup with an HC-10, 12s or 12 used intermittently with short hoses. With a 10 gpm flow requirement the max velocity (intermittent use with short line) is 20 ft/sec so the pressure hose size needs to be at least a -8. If you draw lines for the return and suction, you would get -10 (return) and -16 (suction) recommended hose sizes.

Many trucks have a hydraulic-driven compressor such as the AC-40, Vanair RC40, VMAC H40 or the Vanair RS85. These compressors have various flow requirements and use cases where the recommended hose sizes are:

- AC-40 (intermittent use, recip): 12 gpm (1650 psi, 2100 psi max) -8 pressure, -10 return and -16 suction

- Vanair RC40 (intermittent use recip): 12 gpm (1950 psi, 2275 psi max) -8 pressure, -10 return and -16 suction

- Vanair RC40 (continuous use recip): 12 gpm (1950 psi, 2275 psi max) -10 pressure, -16 return and -24 suction

- VMAC H40 (continuous use, rotary screw): up to 14 gpm (2400 psi, 2800 psi max) -10 pressure, -16 return and -24 suction

- Vanair RS85 (continuous use, rotary screw): up to 20 gpm (2440 psi, 2950 psi max) -12 pressure, -20 return and -32 suction

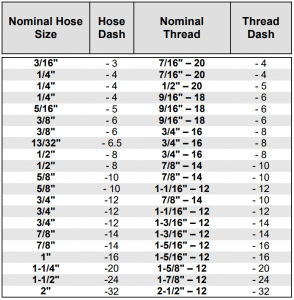

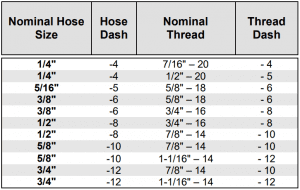

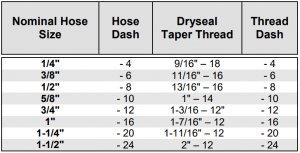

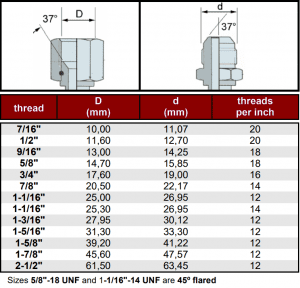

NOTE: The charts below show the various fitting sizes compared to the hose ID sizes which do not always match.

JIC Flare

SAE 45° Flare

O-Ring Face Seal

JIC Connections (ISO 8434)

Oil Type

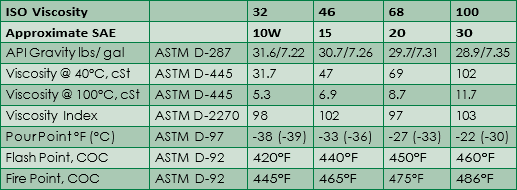

ISO Designation of Hydraulic Oils

International Standardization Organization (ISO) established a viscosity grading (VG) system for industrial hydraulic oils. According to the system hydraulic oils are designated by the letters ISO followed by a number equal to the oil viscosity measured in centistokes at 40°C (104°F): ISO VG 32, ISO VG 46, etc.

NOTE: ISO grades do not match SAE grades. For instance the 100°C viscosity of ISO 68 matches SAE 20 grade.

The following table lists the key parameters of various ISO grade oils.

Ambient Temperature

Oil viscosity is rated at 40°C (104°F) and 100°C (212°F). At low operating temperatures, high viscosity oils negatively affect the efficiency of the hydraulic system, resulting in reduced system performance, and worse yet, can result in lubricant starvation and cavitation of the pump damaging equipment. For this reason ambient temperature performance must be taken into account when selecting an oil.

Auto Crane uses Superfilm AW 5W20 hydraulic oil with -17°C (0°F) to 43°C (110°F) ambient performance with a 82°C (180°F) max operating temp. This oil is not suited for extreme cold environments since the pour point is 0°F. Links to the datasheet and SDS are included below.

The recommended hydraulic oil weight with anti-wear (AW) properties from lowest ambient temperature to highest is as follows:

- MIL-PRF-5606G: Below -10°F (-23°C) ambient (see note below)

- ISO 32 or equivalent: -10°F to 85°F ( -23°C to 30°C) ambient

- ISO 46 or equivalent: 10°F to 110°F ( -12°C to 43°C) ambient

- ISO 68 or equivalent: 10°F to 110°F ( -12°C to 43°C) ambient

Mobil gives these hydraulic oil recommendations based on the these ranges of ambient temperatures:

- Consult Mobil for arctic conditions (800.662.4525)

- Mobil DTE 11M: -13°F to 85°F (-25°C to 30°C) ambient

- Mobil DTE 13M: 0°F to 90°F (-18°C to 32°C) ambient

- Mobil DTE 25: Above 90°F (32°C) ambient

This chart list equivalent oils of common brands:

| Oil Weight | Conoco | Mobil | Shell | Chevron | Exxon | Texaco |

| ISO 32 | Super Hydraulic MV 32, SAE 5W20 | Hydraulic Oil 13 DTE 12M DTE 13M DTE23 |

Tellus T 32 | AW Hydraulic HD 32 | Humble Hydraulic 1193 Univis J-26 Univis N 32 |

Rando HDZ 32 |

| ISO 32 | Super Hydraulic 32, SAE 10W, ISO 32 | Hydraulic AW32 Hydraulic Oil Light DTE 24 ETNA 24 |

AW Hydraulic 32 Tellus 25 Tellus 32 Tellus 927 Tellus Plus 22 |

AW Hydraulic Oil 32 AW Machine Oil 32 Rykon Oil AW 32 Rykon Oil 32 |

Humble Hydraulic 1193 Humble Hydraulic H32 Humble Hydraulic H34 Nuto H44 |

Rando HD 32 |

| ISO 32 | Ecoterra 32, SAE 10, ISO 32 | DTE Excel 32 | Tellus S 32 | Clarity Hydraulic AW 32 | Terrastic EP 32 | Rando HD Ashless |

| ISO 46 | Super Hydraulic 46, SAE 10W, ISO 46 | DTE 25 ETNA 25 Hydraulic Oil AW 46 Hydraulic Oil Medium Hydrex AW 46 NS 46 Vacrex 46 |

AW Hydraulic 46 MD Hydraulic Oil AW 46 Tellus 29 Tellus 46 Tellus 929 Tellus Plus 46 |

AW Hydraulic Oil 46 AW Machine Oil 46 EP Industrial Oil 46 EP Machine Oil 11 Hydraulic Oil 46 Rykon Oil AW 46 |

Humble Hydraulic 1194 Humble Hydraulic H46 Humble Hydraulic M46 Nuto H46 Nuto H48 |

Rando HD 46 |

| ISO 68 | Super Hydraulic 68, SAE 20W, ISO 68 | Hydraulic Oil 68 Hydraulic Oil Heavy DTE 26 ETNA 26 |

AW Hydraulic 68 Tellus 33 Tellus 68 Tellus 933 Tellus Plus 68 |

AW Hydraulic Oil 68 AW Machine Oil 68 EP Machine Oil 68 EP Machine Oil 70 |

Humble Hydraulic 1197 Humble Hydraulic H68 Nuto H54 Nuto H68 |

Rando HD 68 |

NOTE: Extreme cold weather requires the use of an aircraft-grade oil to prevent starving oil and damaging the pump. MIL-PRF-5606G specification hydraulic oils perform from -65°F to 275°F (-54°C to 135°C) when pressurized.

Anderol Royco 756, Shell ASF 41, Castrol Castrolaero H515, BP Univis J41 and Mobil Aero HF are example products.

Automatic Transmission Fluid

Q: Can I use ATF oil instead of hydraulic oil?

A: Short answer, yes!

ATF is a premium hydraulic fluid, but also comes at a premium price, which is its major downside. A gallon of ATF is hard to find for less than $30, but five gallons of hydraulic oil can be had for less than $60. However, ATF is closer in quality to synthetic hydraulic fluid making the choice seem more reasonable.

ATF is formulated for high viscosity index (the ability to maintain test viscosity over a wide temperature range) and has excellent water control properties allowing the fluid to hold more water in saturation before being released to create corrosion. Also, the additives in ATF are formulated to improve lubricity, anti-foaming, shear stability and resistance to oxidation.

Oil Cleanliness

Proportional hydraulic systems require extra care to maintain clean oil. New hydraulic oil is not “clean” hydraulic oil. New oil is typically ISO 4406: 22/21/19 cleanliness whereas proportional controls require oil that is at least ISO 4406: 17/15/12 cleanliness. Using new oil that does not meet this cleanliness means the oil is 32-125x dirtier than what is required!

While the NexStar cranes feature a 5 micron pressure filter to help prevent deposits from reaching the proportional valves, you must insure the oil and hydraulic tank and lines must be clean before running the crane for the first time. Failure to do so will result in contamination problems for your customer.

Last Update: June 26, 2017

Tell us how can we improve this post.

Log In is required for submitting new question.